Introduction

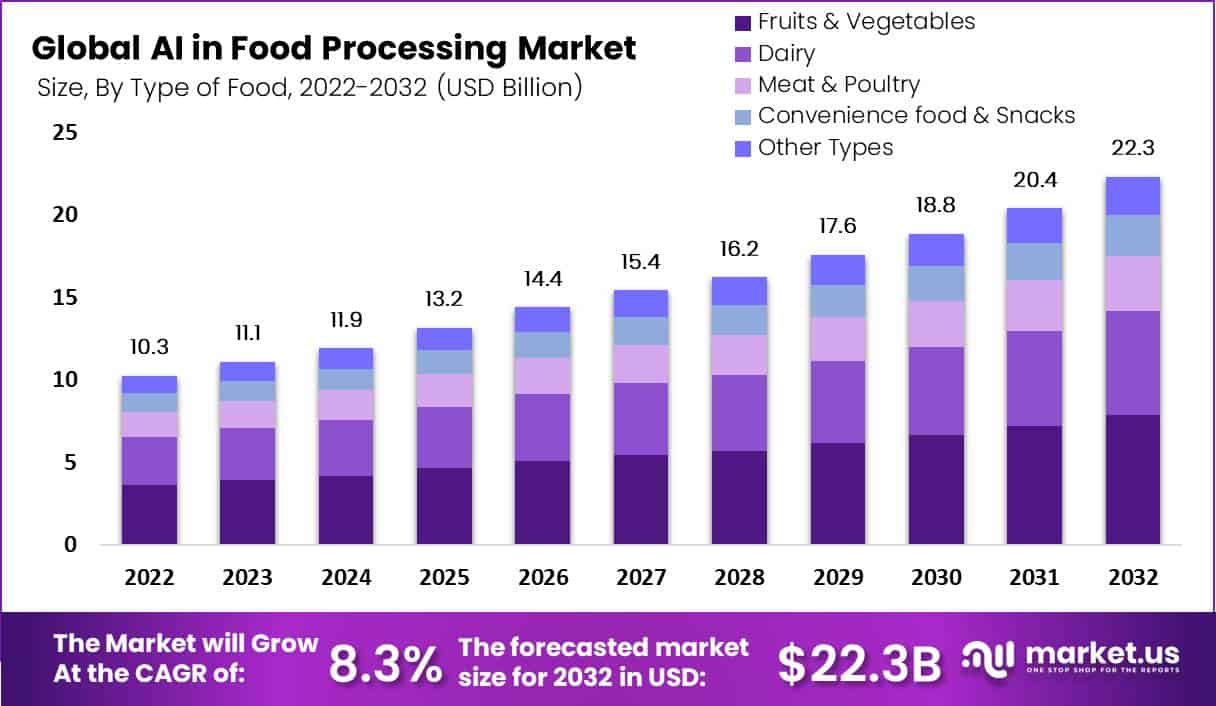

The Global AI in Food Processing Market is projected to reach about USD 22.3 Billion by 2032, up from USD 11.1 Billion in 2023, growing at a CAGR of 8.3% during the forecast period from 2023 to 2032. This growth reflects the rising adoption of AI technologies to improve efficiency, reduce waste, and enhance quality control across the food industry.

Artificial Intelligence (AI) in the food processing market is revolutionizing how food products are manufactured, monitored, and delivered. AI-driven automation and robotics are transforming traditional food processing lines by making them more precise and consistent, enabling faster and safer operations with less human intervention. The technology supports tasks like sorting, cutting, packaging, and quality control with high accuracy. These smart systems can adapt in real-time to variations in raw materials, helping maintain product uniformity and reduce waste.

The integration of AI also enhances food safety through continuous monitoring of storage, hygiene, and contamination risks, ensuring compliance with strict safety standards while reducing potential recalls and health hazards. Several top driving factors are pushing AI adoption in food processing. Efficiency improvement is critical as AI automates repetitive tasks and speeds up production with precision. The ability to reduce food waste by optimizing inventory and demand forecasting plays a significant role, especially for highly perishable items.

Moreover, AI-driven quality control ensures consistent product safety and hygiene, which is vital for consumer trust and regulatory compliance. Businesses are motivated to use AI because it helps them respond quickly to market changes, scale production flexibly, and innovate faster with customized food formulations driven by consumer dietary preferences and trends.

According to the University of Nottingham, nearly 30% of a food processing plant’s energy and water is consumed by equipment cleaning. Their AI-driven sensor technology offers a transformative solution, with the potential to save about $133 million annually by reducing cleaning time by half. This not only supports operational cost savings but also contributes to sustainability goals through lower energy and water consumption.

Analysts’ Viewpoint

Investment opportunities are emerging in AI-driven automation equipment, software platforms for demand forecasting, and AI-powered quality inspection tools. Companies that provide AI solutions for production optimization, supply chain transparency, and food safety compliance stand to capture increasing demand as industry players modernize their systems. Startups and technology providers focusing on integrating AI into legacy food processing lines or developing new AI-based food innovation tools could attract significant investments.

The business benefits of AI adoption in food processing are extensive. Enhanced efficiency leads to higher throughput and lower operational costs. Improved product uniformity and safety boost consumer confidence and brand reputation. The reduction of waste and spoilage enhances profitability and aligns with sustainability goals, increasingly important to stakeholders. AI-enabled predictive maintenance decreases downtime and extends equipment life, reducing capital expenditures.

Regulatory environment for AI in food processing is evolving rapidly to address issues like algorithm transparency, data security, and validation of AI decision-making. Regulators are focusing on ensuring that AI systems used at critical control points in food manufacturing are reliable and accountable. Documentation and auditing of AI training data and performance can be required to comply with food safety laws. Different countries have varying guidelines; for example, some jurisdictions mandate explicit disclosure of AI involvement in product formulation or safety checks.

Driver Analysis

Increasing Demand for Process Efficiency and Food Safety

Food manufacturers face growing pressure to operate more efficiently while ensuring food safety. AI helps meet this demand by automating repetitive tasks and optimizing production processes, which reduces waste and cuts costs. It also allows real-time monitoring and quality checks to prevent contamination and defects, making the food supply safer for consumers. This combination of improved efficiency and enhanced safety is a key factor driving AI adoption in food processing worldwide.

AI-powered quality control systems, such as computer vision, inspect products continuously, catching defects that humans might miss. This not only boosts product consistency but also supports compliance with strict safety regulations, reducing the risk of costly recalls. As manufacturers seek reliable ways to produce safe food while maintaining profitability, AI’s role becomes increasingly essential in modern food processing operations.

Restraint Analysis

High Initial Investment Costs

One major barrier to widespread AI adoption in food processing is the high upfront cost. Installing AI technology requires substantial spending on new hardware, software, and upgrading infrastructure. Beyond equipment, training staff to use AI systems adds to the overall expense, which can be especially challenging for small and medium-sized food producers operating on tighter budgets.

Because of these costs, many companies hesitate to invest in AI, limiting its penetration in the food processing sector. However, as technology evolves, prices are expected to fall, and more cost-effective AI solutions will likely emerge. But currently, the initial financial commitment remains a key obstacle slowing down faster adoption of AI in food manufacturing.

Opportunity Analysis

Expansion into Emerging Markets

Emerging markets with rising urbanization and expanding middle classes represent a promising opportunity for AI in food processing. These regions demand more processed and packaged foods but often lack efficient production methods and reliable quality control systems. AI can help by improving production efficiency, ensuring food safety, and optimizing supply chain logistics, reducing waste and meeting growing consumer needs.

By introducing AI solutions tailored to challenges in these markets, food processors can tap into significant growth potential. Companies that successfully implement AI tools in emerging markets stand to gain new revenue streams while helping these regions modernize their food industries, improving product quality and availability for millions of consumers.

Challenge Analysis

Need for Skilled Personnel

Implementing and maintaining AI technology requires skilled workers who understand both food processing and advanced AI systems. Many food companies struggle to find or train staff who can manage AI tools effectively. This talent gap creates a challenge because without proper expertise, the benefits of AI cannot be fully realized, and operations may suffer from inefficient use or technical failures.

Moreover, investing in workforce training adds to the cost and complexity of AI adoption. Smaller food processors especially face difficulties in recruiting or upskilling employees for emerging AI roles. This shortage of qualified personnel acts as a bottleneck, limiting AI’s broader impact and slowing the pace at which food processors can modernize their operations in a competitive market.

Key Market Segments

Type of Food

- Dairy

- Meat & Poultry

- Convenience food & Snacks

- Fruits & Vegetables

- Other Types

Application

- Food Sorting

- Maintenance

- Production and Packaging

- Quality Control & Safety Compliance

- Customer Engagement

- Other application

Top Market Leaders

- Rockwell Automation Inc.

- Key Technology Inc.

- Sight Machine Inc.

- Honeywell International Inc.

- Raytec Vision SpA

- ABB ltd.

- Sesotec GmbH

- Martec of Whitell Ltd.

- Bratney Companies

- Agco Corporation

- TOMRA

- Other Key Players

Source @ https://market.us/report/ai-in-food-processing-market/