Introduction

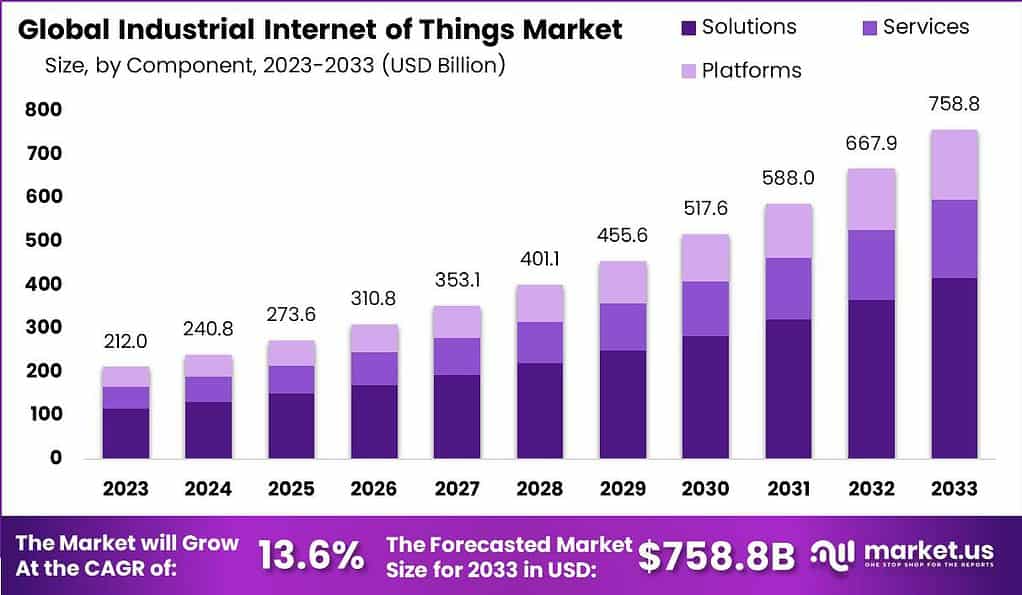

the Global IIoT Market was valued at USD 212.0 billion in 2023 and is projected to reach USD 758.8 billion by 2033. This expansion reflects a strong CAGR of 13.6% over the forecast period, driven by rising automation, digital transformation of factories, and increased use of real-time industrial data. The market is increasingly positioned as a core enabler of smart manufacturing, predictive maintenance, and operational efficiency across heavy industries.

Industrial Internet of Things (IIoT) refers to the network of connected sensors, machines, and devices that collect and exchange data to improve industrial operations. In IIoT systems, physical equipment in factories, plants, and supply chains is fitted with sensors and communication modules that send real-time data to analytics platforms.

This enables monitoring of machine conditions, optimisation of processes, predictive maintenance, and better decision making. IIoT is applied in sectors such as manufacturing, energy, transportation, and logistics to increase productivity, reduce downtime, and improve safety. The technology supports digital transformation by linking production systems with data insights and automation.

The top driving factors for the IIoT market are linked to rising demand for operational efficiency and cost reduction in industrial environments. Manufacturers and operators face pressure to improve asset utilisation and reduce unplanned equipment failures. IIoT provides visibility into machine performance, energy use, and workflow bottlenecks, supporting data-driven maintenance and process improvements.

The growth of cloud computing, edge analytics, and low-cost sensors has made it easier and more economical to deploy IIoT solutions. Regulatory requirements for safety and emissions reporting also support investment in connected systems that can capture and report compliance data automatically.

Demand analysis shows that interest in IIoT continues to grow as industries pursue smarter and more flexible operations. Organisations are using IIoT to enable predictive maintenance that reduces downtime and lowers maintenance costs. Real-time monitoring also helps manage supply chain movements, track inventory, and respond faster to market changes.

Sectors such as automotive production, oil and gas, and utilities place high value on data that improves process reliability and product quality. Small and medium sized enterprises have begun adopting IIoT through modular and scalable solutions that fit limited budgets. As digital strategies mature across industrial sectors, investment in IIoT is expected to remain strong to support productivity gains and competitive advantage.

Top Key Takeaways

- The global IIoT market size stood at USD 212.0 billion in 2023, indicating strong existing industrial adoption.

- Market value is expected to rise to USD 758.8 billion by 2033, reflecting sustained long-term expansion.

- The market is forecast to grow at a CAGR of 13.6% during the period from 2024 to 2033.

- Asia-Pacific accounted for the largest regional share in 2023, supported by large-scale manufacturing and rapid industrial automation.

- Manufacturing remained the leading application segment due to widespread use of smart factories and predictive maintenance systems.

- IIoT solutions represented the dominant component segment, driven by demand for end-to-end monitoring and control systems.

- Adoption is strongly influenced by the need to reduce unplanned downtime, optimize energy usage, and enable real-time decision making across industrial operations.

Key Statistics

- According to sqmagazine, smart home devices represent 32% of global consumer IoT usage, showing strong adoption in everyday living environments.

- In healthcare, IoT wearables have improved patient compliance by 47%, supporting better monitoring and treatment adherence.

- Industrial IoT now accounts for 60% of all new IoT installations, with manufacturing playing the leading role.

- Manufacturing is the largest IoT adopter in 2025, responsible for 34% of total IoT device deployments worldwide.

- Healthcare IoT adoption continues to rise, with 89% of hospitals in developed countries using connected monitoring or diagnostic tools.

- Agriculture is seeing steady growth in IoT use, with 28% of farms globally adopting smart irrigation systems.

- Retail IoT adoption has reached 61%, mainly focused on inventory automation and customer behavior tracking.

- The construction sector reports 39% IoT penetration, driven by safety monitoring and resource management needs.

- Energy and utility providers use IoT in 67% of grid systems worldwide, improving monitoring and operational control.

- Educational institutions have adopted IoT across 44% of campuses globally, using smart ID systems, asset tracking, and learning analytics.

- Transportation and logistics lead in operational usage, with 72% of fleet systems using IoT for route planning and vehicle diagnostics.

- The hospitality industry reached 58% IoT adoption in 2025, enabling automated check-ins, keyless entry, and occupancy monitoring.

- Public sector IoT adoption stands at 49%, focusing on surveillance, waste management, and emergency response services.

- Based on Itransition, about 28% of manufacturing companies in the European Union use IoT to monitor and track the maintenance needs of industrial machinery.

- The manufacturing segment of the IoT-based asset tracking and monitoring applications market is expected to reach USD 2.9 billion by 2033, reflecting steady adoption across industrial operations.

- Around 18% of EU manufacturing firms deploy IoT sensors for warehouse management, supporting better inventory visibility and operational control.

Key Market Segment

By Component

- Hardware

- Software

- Services

By Deployment Mode

- On-premises

- Cloud-based

By Application

- Manufacturing

- Energy and Power

- Oil and Gas

- Transportation and Logistics

- Healthcare

- Others

By End-Use Industry

- Discrete Manufacturing

- Process Industries

- Utilities

- Automotive

- Chemicals

- Food and Beverages

By Region

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

Top Key Players

- ABB Ltd.

- Siemens AG

- IBM Corporation

- Intel Corporation

- Schneider Electric SE

- Rockwell Automation, Inc.

- Honeywell International Inc.

- General Electric Co.

- NEC Corporation

- Cisco Systems, Inc.

- Amazon Web Services, Inc.

- PTC Inc.

- Other Key Players

Use Cases

Predictive Maintenance

IIoT is widely used to monitor the health of industrial equipment in real time. Sensors track vibration, temperature, and operating conditions to detect early signs of failure. Maintenance activities can be scheduled before breakdowns occur, which reduces downtime and extends asset life.

Smart Manufacturing and Process Automation

Factories use IIoT to connect machines, production lines, and control systems. Real time data improves visibility into production performance and process stability. This supports faster decision making, higher output quality, and reduced material waste.

Energy Management and Optimization

IIoT solutions are applied to monitor energy consumption across plants and facilities. Connected meters and sensors help identify inefficiencies in power usage. Energy optimization supports cost control and helps industries meet sustainability and compliance goals.

Supply Chain and Asset Tracking

IIoT enables continuous tracking of raw materials, components, and finished goods. Sensors and connected devices provide location and condition data during storage and transport. This improves inventory accuracy, reduces losses, and enhances delivery reliability.

Quality Control and Inspection

Manufacturers use IIoT to monitor product quality during each stage of production. Sensors and vision systems detect defects in real time. Early identification of quality issues reduces rework and improves customer satisfaction.

Worker Safety and Environmental Monitoring

IIoT devices are deployed to monitor workplace conditions such as air quality, gas leaks, and noise levels. Wearable sensors help track worker location and exposure to hazardous conditions. This supports faster response to safety incidents and improves compliance with regulations.

Recent Development

- Oct, 2025 – ABB was named a Leader in the 2025 Verdantix Green Quadrant for Industrial AI Analytics, highlighting its data integration and analytics performance within industrial IoT environments.

- Jan, 2025 – IBM introduced enhanced AI-driven edge computing solutions enabling real-time data processing and advanced analytics for industrial IoT deployments, supporting greater automation across manufacturing and infrastructure sectors.

Conclusion

The Industrial Internet of Things market is becoming a foundational layer for modern industrial operations as organizations focus on efficiency, reliability, and smarter decision making. Connected industrial systems are enabling real-time visibility across assets and processes, helping companies move from reactive maintenance to proactive and predictive models. This shift is improving productivity while reducing operational risks and downtime.

As industrial environments continue to evolve, IIoT adoption is expected to deepen across both discrete and process industries. Ongoing improvements in connectivity, analytics, and system interoperability are likely to support wider implementation across regions. Over time, IIoT will remain a key driver of industrial digital transformation, supporting smarter factories, resilient supply chains, and more sustainable operations.

Read More – https://market.us/report/industrial-internet-of-things-market/