Introduction

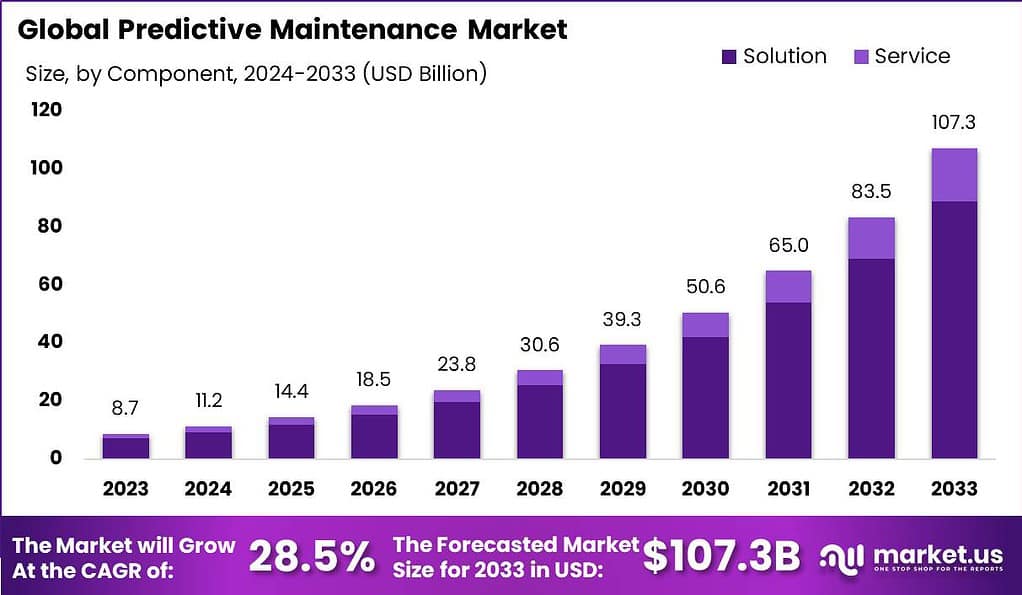

The Global Predictive Maintenance Market is expected to grow from about USD 8.7 billion in 2023 to around USD 107.3 billion by 2033, at a very fast CAGR of 28.5%, as industries use IoT, AI, and analytics to prevent equipment failures, cut downtime, and lower maintenance costs. Predictive maintenance refers to the use of data, sensors, and analytics to forecast equipment failures before they occur so that repairs can be planned rather than reacted to. This approach uses real-time and historical data to identify patterns that signal wear, faults, or performance degradation.

Predictive maintenance systems combine condition monitoring, machine learning models, and often Internet of Things (IoT) connectivity to deliver actionable insights. The goal is to improve asset reliability and reduce unplanned downtime by scheduling maintenance activities when they are most needed. This practice is widely adopted across sectors such as manufacturing, energy, transportation, and utilities where equipment uptime directly affects productivity and cost.

The key driving factors for the predictive maintenance market include a growing focus on operational efficiency and cost reduction. Traditional reactive maintenance leads to unexpected breakdowns and high repair costs, while scheduled maintenance can result in unnecessary servicing. Predictive maintenance offers a data-driven alternative that optimises maintenance frequency and prevents failures.

The increasing availability of low-cost sensors and advanced analytics makes it practical for organisations to monitor critical assets continuously. Pressure to improve safety, extend equipment life, and comply with quality standards further supports investment in predictive solutions.

Demand for predictive maintenance continues to rise as businesses seek to enhance reliability and reduce total cost of ownership for their assets. Industry digital transformation initiatives place strong emphasis on real-time monitoring and intelligent decision support, which align directly with predictive maintenance capabilities. The adoption of IoT infrastructure and cloud computing has lowered barriers to entry, enabling small and mid-size operators to implement predictive systems.

Organisations with asset-intensive operations see measurable gains in throughput and service continuity when unplanned downtime is reduced. As competitive pressures and customer expectations grow, predictive maintenance is increasingly viewed as an essential part of modern asset management rather than an optional enhancement.

Top Key Takeaways

- Solutions (integrated and standalone) hold more than 83% of the market, reflecting strong demand for software platforms that analyze equipment data and predict failures.

- On-premise deployments account for over 71% share, favored in industries with strict data and reliability requirements, while cloud-based models are rising from a smaller base.

- Large enterprises represent more than 75% of spending, as they operate many high-value assets and can justify higher upfront investments.

- Vibration monitoring is the leading technique with over 28% share, widely used to detect early mechanical issues in motors, bearings, and rotating equipment.

- Manufacturing is the top end-use segment with more than 29% share, followed by sectors like energy, automotive, and oil and gas.

- North America leads regionally with over 35% share and about USD 3.05 billion in revenue, driven by strong tech infrastructure and Industry 4.0 adoption.

Key Statistics

- According to GetSockeye, 30% to 40% of industrial facilities are already using predictive maintenance, indicating steady adoption across manufacturing and industrial operations.

- Around 38% of surveyed facilities plan to implement predictive maintenance and analytics, showing strong future intent.

- Implementing predictive maintenance helps organizations reduce unplanned machine downtime by up to 50%, improving operational reliability.

- About 85% of teams report better accuracy in downtime forecasting after adopting predictive maintenance techniques.

- Nearly 55% of industrial plants see higher maintenance staff productivity following predictive maintenance implementation.

- Around 70% of industrial businesses consider predictive maintenance a strategic priority, reflecting its importance in long-term operations planning.

- Approximately 42% of manufacturers identify downtime reduction as the main driver for investing in predictive maintenance solutions.

- Based on WorkTrek, 30% of facilities currently use predictive maintenance, showing moderate adoption across industrial environments.

- About 79% of facilities actively involve technicians in predictive maintenance programs, highlighting the importance of human expertise alongside analytics.

- Only 11% of facilities have reached Level 4 predictive maintenance maturity, indicating that advanced implementation remains limited.

- Predictive maintenance can lower maintenance and operational costs by up to 25%, delivering measurable financial benefits.

- Around 47% of organizations say improving uptime is the primary objective behind adopting predictive maintenance strategies.

- Predictive maintenance helps increase equipment uptime by 10% to 20%, improving asset reliability and performance.

- Nearly 60% of respondents state that data availability is critical to the success of predictive maintenance initiatives.

- At the same time, 51% of facilities are not planning to adopt predictive maintenance, reflecting ongoing barriers such as cost, data readiness, and skill gaps.

- Gitnux reports that, preventive maintenance delivers cost savings of 12% to 18% when compared with reactive maintenance approaches.

- Predictive maintenance helps organizations cut overall maintenance costs by 25% to 30%, driven by better planning and early fault detection.

- Shifting from reactive to predictive maintenance can reduce maintenance-related expenses by 30% to 40%, improving long-term cost control.

- Preventive maintenance can lower equipment breakdowns by 70% to 75%, supporting higher asset reliability and longer equipment life.

- Predictive maintenance reduces machine downtime by 35% to 50%, helping maintain consistent production levels.

- Around 82% of companies have faced unplanned downtime within the past three years, highlighting the widespread impact of unexpected failures.

- Approximately 30% of manufacturing accidents are linked to maintenance activities, emphasizing the safety risks of poor maintenance practices.

- Regular preventive maintenance can reduce accident risks by about 60%, contributing to safer industrial environments.

Use Cases

Manufacturing Equipment Monitoring

Sensors and analytics are used to track machine health. Failures are predicted before breakdowns occur, helping reduce unplanned downtime.

Industrial Asset Maintenance

Critical assets such as motors, pumps, and compressors are continuously monitored. Maintenance is scheduled based on actual equipment condition rather than fixed intervals.

Energy and Utilities Infrastructure

Power plants, wind turbines, and grid equipment are monitored to detect early signs of wear. This helps prevent outages and improves asset reliability.

Transportation and Logistics Fleets

Vehicles, rail systems, and aircraft components are analyzed using real time data. Maintenance is planned in advance to avoid service disruptions and improve safety.

Building and Facility Management

Systems such as HVAC, elevators, and electrical equipment are monitored. Potential faults are identified early, reducing repair costs and improving operational efficiency.

Key Market Segment

By component

- Solution

- Integrated

- Standalone

- Service

- Integration and Deployment

- Support & Maintenance

- Training & Consulting

By deployment model

- Cloud

- On-premise

By enterprise size

- Small & Medium Enterprises

- Large Enterprises

By monitoring technique

- Torque Monitoring

- Vibration Monitoring

- Oil Analysis

- Thermography

- Corrosion Monitoring

- Others

By end-use

- Aerospace & Defense

- Automotive & Transportation

- Energy & Utilities

- Healthcare

- IT & Telecommunications

- Manufacturing

- Oil & Gas

- Others

Top Key Players

- IBM Corporation

- General Electric (GE)

- SAP SE

- Microsoft Corporation

- PTC Inc.

- Schneider Electric SE

- Siemens AG

- Honeywell International Inc.

- ABB Ltd.

- Bosch.IO

- Rockwell Automation Inc.

- Uptake Technologies Inc.

- Other Key Players

Recent Development

- November, 2025 – IBM promoted its State of Salesforce report showing how clients use IBM Consulting and AI agents to automate workflows, govern data and scale predictive insights across hybrid cloud environments.

- June, 2025 – Siemens presented industrial IoT and AI offerings that support predictive maintenance by analyzing sensor data to avoid unplanned downtime.

Conclusion

The predictive maintenance market is becoming a core pillar of digital operations as industries move from reactive and scheduled maintenance to data-driven, condition-based strategies. Solution-centric, on-premise-heavy deployments used mainly by large enterprises in manufacturing and other asset-intensive sectors now define the market’s structure, with North America in the lead and other regions catching up through Industry 4.0 programs. Despite challenges around data quality, skills shortages, and integration complexity, the combination of IoT, AI, and advanced analytics positions predictive maintenance as a key lever for uptime gains, cost reduction, and better asset management over the next decade.

Read More – https://market.us/report/predictive-maintenance-market/